Nitrile Butadiene Rubber (NBR) powder

250.0 INR/Kilograms

Product Details:

- Width nan

- Usage & Applications Sealing, gasketing, footwear, automotive, rubber compounds, adhesives, hoses, molded goods, transmission belts, rollers, and oil-resistant products

- Tensile Strength Minimum 8 MPa (varies with formulation)

- Material Nitrile Butadiene Rubber (NBR)

- Density 0.99 Gram per cubic centimeter(g/cm3)

- Compression Ratio nan

- Length nan

- Click to view more

X

Nitrile Butadiene Rubber (NBR) powder Price And Quantity

- 500 Kilograms

- 250.0 INR/Kilograms

Nitrile Butadiene Rubber (NBR) powder Product Specifications

- nan

- Minimum 8 MPa (varies with formulation)

- Sealing, gasketing, footwear, automotive, rubber compounds, adhesives, hoses, molded goods, transmission belts, rollers, and oil-resistant products

- 0.99 Gram per cubic centimeter(g/cm3)

- Nitrile Butadiene Rubber (NBR)

- nan

- nan

- Limited (not inherently flame retardant)

- High oil, fuel, abrasion resistance, good flexibility, and processing performance

- Very low

- nan

- White or light beige

- nan

- 40-80 Shore A (variable, as powder used for compounding)

- Synthetic rubber

- Excellent resistance to oils, fuels, and various chemicals

- Powder

- Custom packaging (e.g. 25 kg bags)

- Powder raw material

- 16-18%

- 1.0%

- Butadiene, Acrylonitrile, Additives

- Nitrile Butadiene Rubber

- 1.2%

- -30C to +120C (dependent on formulation)

- Nitrile Butadiene Rubber (NBR) powder

- No (Synthetic)

- Powdered / fine granulate

- nan

- Low

Nitrile Butadiene Rubber (NBR) powder Trade Information

- 5 Days

- No

- Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe

- All India

Product Description

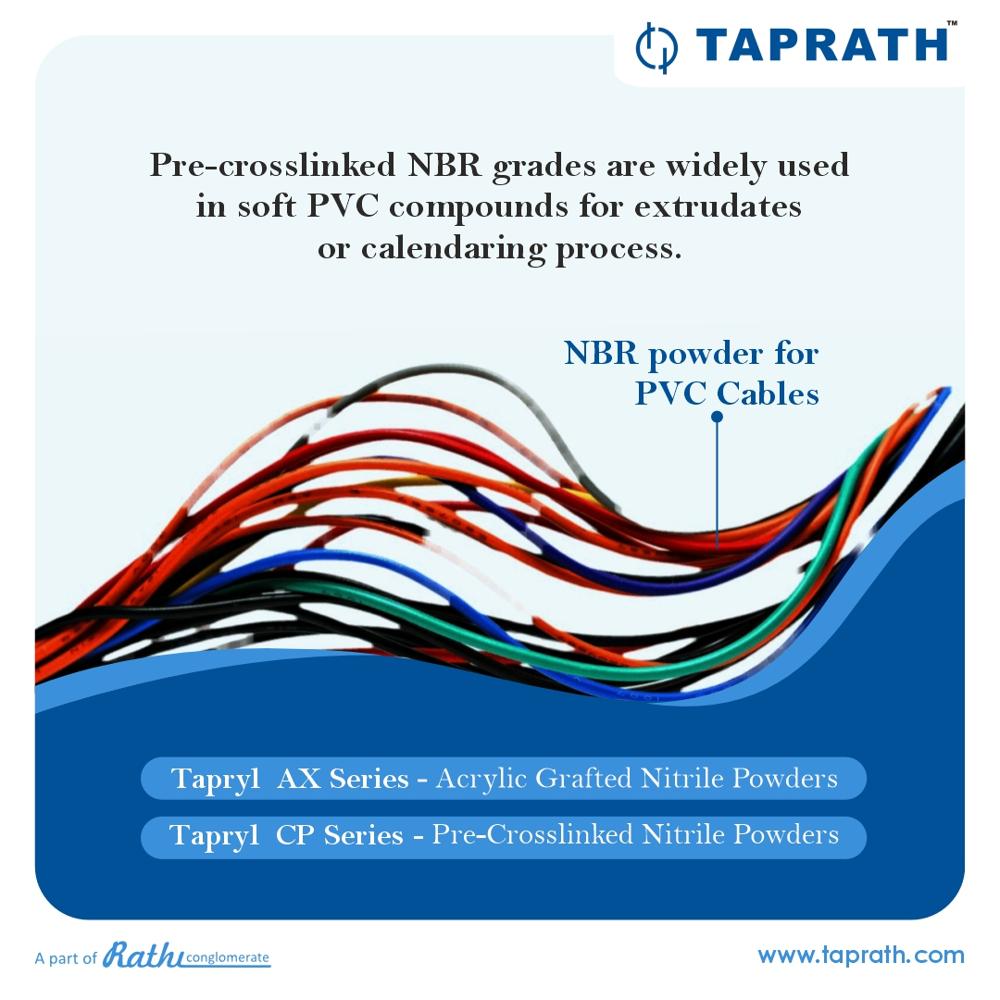

NBR (Nitrile Butadiene Rubber) powders are widely used in friction applications due to their excellent mechanical properties and compatibility with various materials. These powders enhance the performance of friction products like brake pads, clutches, and industrial friction components. Heres a quick overview of their benefits in such applications:

-

Improved Friction Stability: NBR powders provide consistent frictional properties under varying conditions, such as temperature and pressure.

-

Enhanced Wear Resistance: They improve the durability of friction components, reducing wear and extending the lifespan of products.

-

Thermal Stability: NBR has good heat resistance, maintaining performance under high-temperature conditions typical in friction applications.

-

Bonding and Compatibility: NBR powders blend well with other resins, fibers, and fillers, ensuring a uniform distribution in composite materials.

-

Reduced Noise and Vibration: Components using NBR powders exhibit lower noise and vibration, which is critical in automotive and industrial applications.

-

Customizable Properties: NBR powders can be tailored to achieve specific performance needs, such as hardness, elasticity, and compression resistance.

These features make NBR powders a valuable additive in the formulation of high-performance friction materials.

High Performance and Versatility

NBR powder is renowned for its high oil and fuel resistance, along with reliable elongation and tensile strength. It is suitable for a wide temperature range, making it ideal for demanding applications in various industries, including automotive, footwear, and industrial manufacturing.

Optimal Storage and Packaging Solutions

To maintain quality, NBR powder must be stored in cool, dry environments away from direct sunlight and moisture, with a shelf life of 12 months. Packaging options include durable HDPE bags or paper sacks, typically available in custom weights, such as 25 kg bags.

Certified Quality and Safety

Produced under ISO 9001:2015 certification, NBR powder assures consistent quality. Its low ash and volatile matter content, along with high purity, provide dependable performance for rubber compounding and other technical uses.

FAQs of Nitrile Butadiene Rubber (NBR) powder:

Q: How should NBR powder be stored for optimal shelf life?

A: NBR powder should be stored in a cool, dry area, away from direct sunlight and moisture. Proper storage ensures the powder retains its quality for up to 12 months.Q: What makes NBR powder suitable for oil- and fuel-resistant applications?

A: NBR powder is inherently resistant to oils, fuels, and many chemicals due to its unique composition of butadiene and acrylonitrile, delivering excellent performance in harsh environments.Q: Where can NBR powder be effectively used in industry?

A: This product is ideal for use in the manufacture of seals, gaskets, footwear, adhesives, hoses, molded goods, transmission belts, and oil-resistant products, among others.Q: What benefits does NBR powder offer in rubber compounding?

A: NBR powder provides high flexibility, excellent abrasion resistance, and good processing performance, making it an ideal raw material for enhancing both quality and durability in rubber compounds.Q: When should I use NBR powder over natural rubber?

A: NBR powder is preferable when enhanced resistance to oils, fuels, and chemicals is required, as in automotive, industrial, and sealing applications where natural rubber may deteriorate.Q: How does the recommended application temperature of NBR powder affect its performance?

A: The powder maintains optimal properties within -20C to +100C, but can perform in temperatures from -30C to +120C, depending on formulation, making it reliable for products exposed to variable conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Tapryl | Elastomer Powders' category

We are Dealing in only Raw Material of Masterbatches, Raw Compositable Materials, Rubber Powder.

Call Me Free

Call Me Free