Compostable Raw Material

88.0 INR/Kilograms

Product Details:

- Application Manufacturing of Compostable Bags, Cutlery, Packaging

- Solubility Insoluble in Water, Degrades in Compost

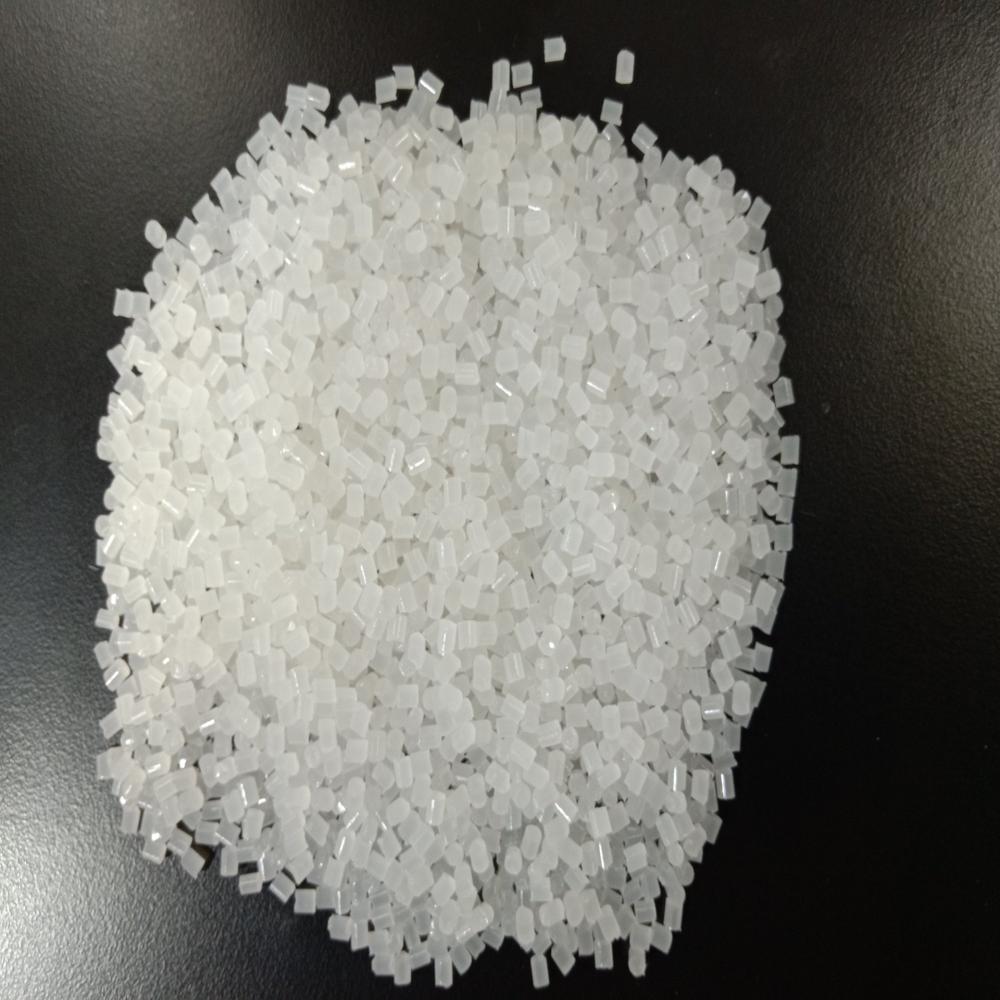

- Appearance Off white to yellowish granules

- Properties Biodegradable, Eco-friendly, Compostable under industrial conditions

- Shelf Life 24 months

- Molecular Weight Variable

- Storage Store in dry, cool, and ventilated place away from direct sunlight.

- Click to view more

X

Compostable Raw Material Price And Quantity

- 500 Kilograms

- 88.0 INR/Kilograms

- Medium

- 2-5 mm granules

- <0.5%

- Complies with ASTM D6400 / EN 13432

- Free from heavy metals

- Up to 170°C

- 20-35 MPa

- 25 kg bags

- Decomposes within 3-6 months in industrial composting

- Off-white / Light yellow

- 90%+

Compostable Raw Material Product Specifications

- Granules

- Insoluble in Water, Degrades in Compost

- N/A (Polymer blend)

- Off white to yellowish granules

- Plant-based Polymers, Natural Additives

- Biodegradable, Eco-friendly, Compostable under industrial conditions

- Store in dry, cool, and ventilated place away from direct sunlight.

- 24 months

- Variable

- Compostable Raw Material

- Manufacturing of Compostable Bags, Cutlery, Packaging

- NO

- Neutral

- Industrial Grade

- Odorless and Tasteless

- Use for extrusion, injection molding to make compostable products.

- Granules

- 7 (neutral)

- 39139090

- 99%

- 1.25 Gram per cubic centimeter(g/cm3)

- 120-160C

- Medium

- 2-5 mm granules

- <0.5%

- Complies with ASTM D6400 / EN 13432

- Free from heavy metals

- Up to 170°C

- 20-35 MPa

- 25 kg bags

- Decomposes within 3-6 months in industrial composting

- Off-white / Light yellow

- 90%+

Compostable Raw Material Trade Information

- 2000 Kilograms Per Week

- 7 Days

- No

- Central America, North America, Asia, Australia, Eastern Europe, Western Europe, South America, Middle East, Africa

- All India

Product Description

TapBiowas created by Taprath Elastomers LLP as a result of this environment-focused approach. By catering compound-based and masterbatch-based solutions to current, already established manufacturers of conventional plastic,newercompostableplastic productscan be produced with minimal change in their current manufacturing process.In a significant shift, Taprath, through its initiative TapBio, has recognized its responsibility toward environmental sustainability. TapBio is the brand under which Taprath manufactures a range of compostable and biodegradable compounds and masterbatches made from bioplastics. These materials are designed to replace traditional plastics in various single-use, disposable products, such as plastic bags, straws, cutlery, plastic-coated paper cups, and more. The applications of TapBio extend from flexible packaging to healthcare and from childrens toys to cosmetics.

The primary concern addressed here is not the utility of plastic but its disposal and recyclability. Single-use plastics have led to massive landfills and polluted oceans, posing an immediate threat to various species. While completely eliminating plastic usage is impractical due to its extensive applications, the alternative is to shift from plastics to compostable materials for single-use products. These compostable materials break down into harmless components like CO2, H2O, and biomass in the presence of micro-organisms, benefiting the soil without introducing toxic substances.

Overall, TapBio represents Tapraths commitment to addressing the environmental challenges associated with single-use plastics and its ambition to make a positive impact in this direction.

High Performance and Sustainability

This compostable raw material exemplifies a balance between robust mechanical properties and environmental stewardship. Its granules boast a tensile strength of 20-35 MPa and stability at temperatures up to 170C, making it suitable for extrusion and injection molding processes. The primary components are plant-based polymers and natural additives, ensuring the product contains more than 90% renewable content.

Certified Biodegradability and Safety

Conforming to ASTM D6400 and EN 13432 standards means this material meets stringent criteria for industrial compostability. Absence of heavy metals and toxic elements ensures safety throughout both usage and decomposition phases. It is non-poisonous, odorless, tasteless, and harmless to the environment, perfect for food-contact applications like cutlery and packaging.

Packaging, Storage, and Shelf Life

Packed in 25 kg bags, this granule-form raw material should be stored in a dry, cool, ventilated environment, away from direct sunlight to maintain its quality. Its 24-month shelf life allows flexibility in inventory management, ensuring consistent supply for manufacturers, exporters, and suppliers.

FAQs of Compostable Raw Material:

Q: How does this compostable raw material decompose in industrial composting?

A: This material breaks down under controlled industrial composting conditions, where factors such as temperature, moisture, and microbial activity facilitate its decomposition. It typically takes 3-6 months to fully degrade, resulting in compost without leaving toxic residues.Q: What are the main applications of this biodegradable granule material?

A: It is primarily used in the manufacturing of compostable bags, cutlery, and various types of eco-friendly packaging. The granules are engineered for extrusion and injection molding, making them versatile for different industrial purposes.Q: When can I expect finished products made with this material to start composting?

A: Products made from this raw material will begin to break down once placed in appropriate industrial composting facilities, which maintain specific temperature, moisture, and microbial conditions. Composting typically initiates almost immediately, with complete decomposition occurring within 3-6 months.Q: Where should this compostable material be stored for best results?

A: For optimal preservation, keep the material in a dry, cool, well-ventilated place, away from direct sunlight. Proper storage extends shelf life up to 24 months, maintaining the granules physical and chemical properties.Q: What is the benefit of choosing this plant-based, compostable raw material?

A: Selecting this material ensures your products are not only high performance but also environmentally responsible. It offers rapid compostability, contains over 90% renewable content, and is certified free from harmful substances, supporting sustainable practices.Q: How can manufacturers process this material into finished products?

A: Manufacturers can utilize standard extrusion and injection molding equipment, using the granules as feedstock to create various compostable goods. The materials thermal stability up to 170C supports conventional processing techniques without compromising compostability.Q: Is this compostable raw material safe for food-contact items?

A: Yes, it is free from toxic elements and heavy metals, odorless, tasteless, and non-poisonous, making it suitable for producing food-contact items such as disposable utensils and packaging.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'TapBio | Compostable raw material' category

We are Dealing in only Raw Material of Masterbatches, Raw Compositable Materials, Rubber Powder.