PPA Master Batch

190.0 INR/Kilograms

Product Details:

- Particle Count Uniform

- Material Polymer Processing Aid

- Shape Cylindrical

- Particle Size 2-3 mm

- Carrier PE (Polyethylene)

- Mesh 30 Mesh

- Usage Processing Aid, Polymer Additive

- Click to view more

X

PPA Master Batch Price And Quantity

- 190.0 INR/Kilograms

- 100 Kilograms

- 24 Months

- Dry, Cool Place

- Up to 230°C

- <0.2%

- 115°C

- Insoluble in water

- Polyethylene, Polypropylene

- 1000-2000 ppm

PPA Master Batch Product Specifications

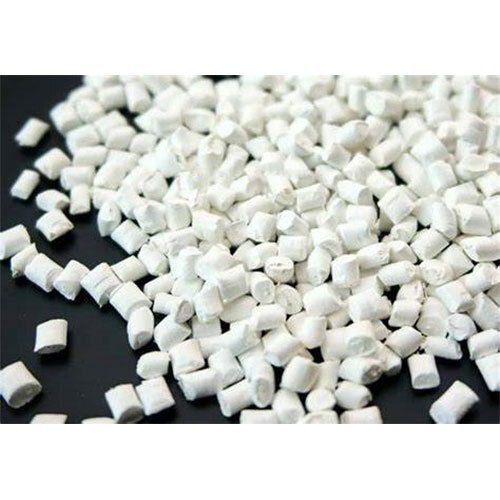

- Cylindrical

- White

- 2-3 mm

- PE (Polyethylene)

- Polymer Processing, Film Extrusion

- 30 Mesh

- Polymer Processing Aid

- Uniform

- 0.95 Gram per cubic centimeter(g/cm3)

- Granules

- Processing Aid, Polymer Additive

- PPA Master Batch

- 99.5%

- 24 Months

- Dry, Cool Place

- Up to 230°C

- <0.2%

- 115°C

- Insoluble in water

- Polyethylene, Polypropylene

- 1000-2000 ppm

PPA Master Batch Trade Information

- 1000 Kilograms Per Month

- 7 Days

- No

- Western Europe, Middle East, Africa, Central America, North America, South America, Eastern Europe, Asia, Australia

- All India

Product Description

The use of PPA is not anymore limited to blown film extrusion exclusively: nowadays PPA are widely used in film production, pipe extrusion, blow molding, wire and cable production, coextrusion, fiber spinning... using LLDPE, MDPE, HDPE, and PP. Recently this list has even extended to non-polyolefins. Polymer Processing Additives (PPA) are frequently used in the plastics industry for the processing of polyethylene and polypropylene.TapStar PPA is suitable for PE & PP available in pellet form for injection, extrusion and blow moulding applications. We also offer TapStar PPA 4032 in powder form for roto-moulding applications.

Features:

- Eliminates melt fracture / Shark skin

- Increases Productivity

- Reduces back pressure

- Reduces die lines / die buildup

- Reduces gel formation during processing

- Improves surface finish and gloss.

- Increase output & Flow.

Applications :

- Wire & Cable

- Blown Film, Cast Film

- Extrusion, Film, Sheet

- Blow mould, Injection mould

- Fiber, Tap, Ropes, Foam

- Pharmaceutical Packaging

- Suitable with Polar & Non-Polar Polymers

Enhance Polymer Processing Performance

Our PPA Master Batch elevates polymer manufacturing by improving flow characteristics and reducing surface defects during film extrusion and other processing applications. Its specialized composition makes it a valuable additive for both polyethylene and polypropylene, supporting consistent output and superior product finishes. Widely used by exporters, manufacturers, and suppliers across India, it is tailored for high-performance industrial use.

Optimal Compatibility and Easy Application

Designed with a polyethylene carrier, this master batch blends seamlessly with PE and PP matrices without agglomeration. Its uniform cylindrical granules and precise particle size support even distribution during mixing, making it convenient to use in existing production processes. The recommended dosage is 1000-2000 ppm, ensuring flexibility for different operational needs.

Reliable Quality and Storage Solutions

With a high purity level and minimal moisture content, this PPA Master Batch ensures product reliability over extended periods. Maintaining storage in a cool, dry place preserves its integrity for up to 24 months, ensuring manufacturers always benefit from consistent quality and processing efficiency.

FAQ's of PPA Master Batch:

Q: How should PPA Master Batch be incorporated into polymer processing?

A: PPA Master Batch should be directly blended with polyethylene or polypropylene resin at the recommended dosage of 1000-2000 ppm. Its uniform, cylindrical granules ensure easy and even dispersion during the mixing stage of film extrusion or other polymer processing applications.Q: What are the key benefits of using PPA Master Batch in film extrusion?

A: This additive enhances polymer melt flow, reduces die build-up, and prevents surface defects, resulting in smoother finishes and greater processing efficiency. It also supports higher productivity and reduced maintenance in extrusion lines.Q: When is the optimal point to add PPA Master Batch during manufacturing?

A: For best results, PPA Master Batch should be introduced at the beginning of the resin blending process before extrusion or molding. This allows complete integration and ensures maximal efficiency during polymer processing.Q: Where is this PPA Master Batch primarily used?

A: It is predominantly utilized in polymer processing units and manufacturing plants involved in film extrusion and the production of polyethylene and polypropylene-based goods throughout India by exporters, manufacturers, and suppliers.Q: What is the process for storing and handling this master batch?

A: The master batch should be kept in a cool, dry place away from direct sunlight and moisture. Proper storage preserves its low moisture content and ensures a 24-month shelf life, maintaining its processing performance.Q: Is the master batch compatible with materials other than PE and PP?

A: Although optimized for polyethylene and polypropylene, it is not recommended for use with incompatible polymers. Its formulation and carrier are specifically designed for PE and PP matrices to achieve desired processing outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Additivo+ | Additive Masterbatches' category

We are Dealing in only Raw Material of Masterbatches, Raw Compositable Materials, Rubber Powder.